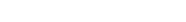

旋转式全自动层压机

该机用于智能卡层合工艺、两组合金铝层压板,重量轻,液压泵变频加压、四压力缸多段变压力层合,PLC控制,采用温度控制模块高精度压力变送频器,压力精度高,温度更均匀,传热快,层压时间短,效率高,节能,环保。本机采用旋转式全自动上料方式,实现上料升降仓、热压仓、冷压仓三个工位仓同步自动进出料,配合翻转装料器使用,只需单人操作,可以大大降低工作强度,安全、高效,运行稳定。

技术参数

层压板面积:550mm*700mm

额定压力:18Mpa

电源电压: AC380V/50Hz

功 率:88kw

层压塔数:2

层压工位:冷热各10个

控制方式:PLC

重 量:7500kg

外形尺寸:4200(L)*4000(W)*2200(H)

可增加减重力装置

l 特点

该机用于智能卡层合工艺、两组合金铝层压板,重量轻,液压泵变频加压、四压力缸多段变压力层合,PLC控制,采用温度控制模块高精度压力变送频器,压力精度高,温度更均匀,传热快,层压时间短,效率高,节能,环保。本机采用旋转式全自动上料方式,实现上料升降仓、热压仓、冷压仓三个工位仓同步自动进出料,配合翻转装料器使用,只需单人操作,可以大大降低工作强度,安全、高效,运行稳定。

l 工作流程

1.在翻转装料器上,将装好的待层压料盘自动送入升降上料仓,升降上料仓满仓后,设备自动将料盘送入旋转上料仓,到位后,旋转上料仓转动,将料盘对准热压仓,设备自动将10个料盘送入热压仓,层压板上升执行热压工作。此时在上料工位又将待层压的料盘送进升降上料仓等待。

2.热压层压完成后,层压板下降,此时设备将热压过的料盘和上料仓待压的料盘同步送入旋转上料仓,到位后,旋转上料仓转动,使热压过的料盘对准冷压仓,此时待压料盘刚好对准热压仓,设备再次同步工作,将待压料盘送入热压仓,热压过的料盘送入冷压仓,料盘到位后,热压仓和冷压仓同时进行压合工作。此时又将待压的料盘装入升降上料仓内等待。

3.热压和冷压工作完成后,热压板和冷压板下降,设备同步将热压仓、冷压仓、上料仓内的料盘同步送入旋转上料仓,旋转上料仓转动,重复第二步的工作。此时冷压好的料盘被送入升降上料仓里,操者可以将压好的料盘换装待压的板张,再送入升降上料仓,等待下一次的层压循环。

这样就实现了自动上下层压料盘的操作。

OVERVIEW

The system specially designed for mass production of big sheet likes 6x8/6x9/7x8 with amazing & innovative design, works in 7x24 industrial concepts!

All loading & unloading jobs will be operated automatically by a smart rotary system. The laminator is able to synchronize the sheets’ feeding and discharging.

The unique tech of Slight-Press Starting will reduce the chip loss rate during RFID card/ inlay pre-lamination, keep the pressure close between upper openings and bottom openings, ensure the sheets lamination in high quality.

With 2 groups’ aluminum-alloy press platens, hydraulic-pump frequency conversion pressing, advanced PLC & temperature control modules, the machine can work well with 4 press cylinders in multistage laminating for excellent results.

The precise pressure control, well-distributed heating, less circle time & higher capacity, energy saving & environment friendly, are the features of such amazing system.

Advanced Heating System

The aluminum-alloy press platen leads the excellent even heating transit, controlled by PLC for high precision temperature & pressure transmitting frequency converter.

15 heating rods in each press platen. Advanced sensor & PLC controls each press layer’s temperature precisely. The heating temperature is up to 220 ℃ with tolerance of ±1℃.

Quick & even heat transferring will shorten the cycle time. High efficiency, energy saving and environment friendly are also advantages.

§ Advanced Pressure Control System

Pressure range 0.1-18MPa, Controlling precision ±0.1 MPa, which achieved by advanced pressure sensor and PLC control system. The top-level hydraulic system will ensure the reliable & stable working.

§ High Pressure Accuracy & Even Temperature

In heat & cold press station, there are 4 hydraulic cylinders working together and pressures controlled by 2 motor and hydraulic pumps

20 years practices authenticated that précised temperature control comes from simple temperature setting!

l Echnical parameter:

Laminating Area: 550mm*700mm

Rated Pressure:18Mpa

Power Voltage: AC380V 50Hz

Consumption:88kw

Opening: Cold/Hot in 10tower each

Contact way:PLC

Weight:7500kg

Dimension :4200mm(L)×4000(W)×2200mm(H)